SUGICUT

Introduction Products :

- Lubricant for cutting processes

- Neat Type Cutting Oil、Water Soluble Cutting Oil

Water Soluble Cutting Oil SUGICUT

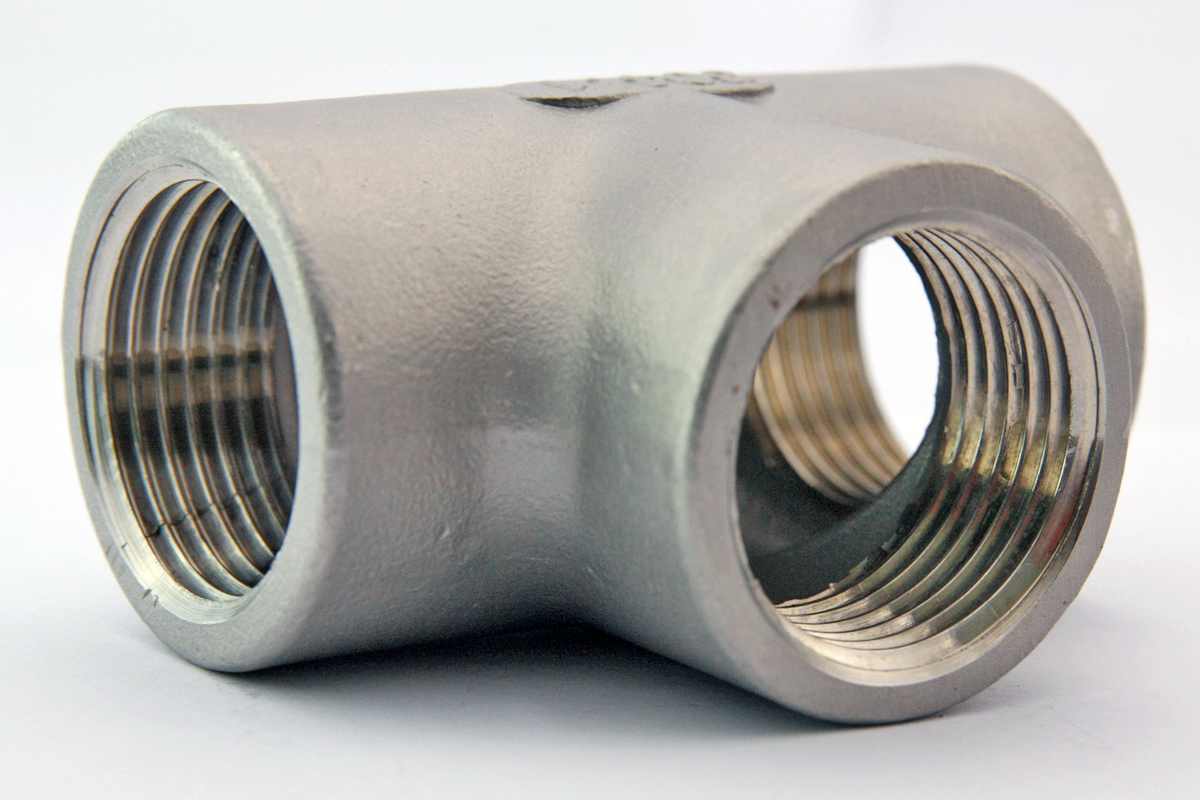

Application :

Lubricating oil for cutting processes using various materials such as steel and non-ferrous.

Merit :

- Improves dimensional accuracy.

- Improves tool life.

- Improves working environment.

Performance :

- Keeping the emulsion stabile

- Good oil drainage

- Good cleaning effect

- Developed based on fully synthetic chemicals

- Excellent antibacterial

- Excellent lubricity, using a variety of synthetic lubricants

| Item | Appearance | PH | Suggestion Concentration | Merit and Application |

| CE-11NB | Light Brown | 9.6(5%) | 5%~10% | Competitive price; steel cutting process |

| CE-14G | Light Brown | 9.7(5%) | 5%~10% | Steel, cast iron; cutting and grinding process |

| CE-18B | Light Brown | 9.6(5%) | 5%~10% | Steel, stainless, and aluminum alloy; cutting and grinding process |

| CE-18KJ |

Light Brown |

9.7(5%) |

5%~10% |

aluminum alloy; cutting and grinding process; non irritating skin product because of amine free |

| CE-18SP | Light Yellow | 9.5(2.5%) | 5%~10% | Steel, iron, aluminum alloy; good anti-corrosion and lubricant properties |

| CE-18SZ |

Yellow |

9.6(2.5%) |

5%~10% |

Steel, iron, aluminum alloy and zinc-aluminum alloy; good lubricant and anti-spoilage properties; for MC cutting machine |

| CE-28B | Light Brown | 9.6(5%) | 5%~10% | Chlorine type extreme pressure agent added; steel, stainless steel cutting process |

| CE-30E | Brown | 9.3(5%) | 5%~10% | Sulfur type extreme pressure agent added; steel, stainless steel and iron cutting process |

| CE-116S | Yellow | 9.5(2.5%) | 5%~10% | Iron workpiece cutting and grinding process; good lubricant property |

| CE-118AL | Light Yellow | 9.5(2.5%) | 5%~10% | aluminum alloy; cutting process; the workpiece will not change color during high temperature process |

| CE-119V |

Yellow |

9.3(2.5%) |

2.5%~10% |

aluminum alloy, Magnesium contained alloy; cutting process; good hard water resistance and defoaming properties |

| CE-132B |

Brown |

9.6(2.5%) |

3.3%~10% |

Sulfur and chlorine series extreme pressure agents, used for cutting and forming of difficult-to-machine materials, and also used in various harsh processes such as drilling, tapping, reaming, etc. |

| CE-1402S | Light Brown | 9.5(2.5%) | 3.3%~10% | Steel and aluminum alloy; cutting and grinding process |

| Item | Appearance | PH | Suggestion Concentration | Merit and Application |

| CS-64TZ | Yellow | 9.7(2.5%) | 2.5%~10% | Iron type workpiece; cutting process |

| CS-64SB | Light Brown | 10.0(5%) | 2.5%~5% | Steel, cast iron and aluminum; easily be cleaned |

| CS-164ST | Yellow | 9.5(2.5%) | 3.3%~10% | Steel, iron, copper; cutting and grinding process |

| CS-164F |

Yellow |

9.2(2.5%) |

2.5%~5% |

For iron-based materials.Excellent sedimentation performance, the fluid is not easy to change color, greatly life of the cutting fluid. |

| CS-164K |

Yellow |

9.9(2.5%) |

5%~10% |

For magnesium alloy cutting processing, has excellent corrosion resistance, and has very good stability in hard water, and keep clean processing environment |

| CS-168A | Yellow | 9.1(2.5%) | 2.5%~5% | Alluminum alloy, steel and cast iron; cutting and grinding process |

| Item | Appearance | PH | Suggestion Concentration | Merit and Application |

| CS-52CW | Yellow | 9.3(5%) | 2.5%~5% | Cemented carbide alloy; cutting process; CS-52CW can control the |

| CS-53HF |

Light Yellow |

9.5(5%) |

2%~5% |

Steel and cast iron; cutting process; CS-53HF has good oil and water separation properties. |

| CS-53GB | Green | 9.7(2.5%) | 3.3%~10% | Steel and cast iron; cutting process |

| CS-55SP |

Light Yellow |

8.8(5%) |

2.5%~5% |

Sapphire wafer cutting; enhance the precision of wafer and the lifespan of cutting tool; good powder settleability in liquid and easily be cleaned |

| CS-58XJ | Light Yellow | 9.0(5%) | 2.5%~5% | Iron workpiece; cutting and grinding process; MC process use fully synthetic oil. |

| CS-92 | Transparent | 9.2(2.5%) | 2.5%~5% | Iron workpiece; cutting and grinding process; MC process use fully synthetic oil. |

| CS-157FS |

Yellow |

9.5(2.5%) |

2.5%~5% |

Cast iron, iron, steel and stainless steel; cutting and grinding process; good oil-water separation properties; good performance in bearing grinding process |

| CS-158G | Yellow | 8.9(2.5%) | 2.5%~5% | Optical glass; grinding process; special lubricant added |

| CS-158KS | Transparent | 8.6(2.5%) | 2.5%~5% | Cast iron, iron, steel and stainless; grinding process |

Cutting Oil SUGICUT

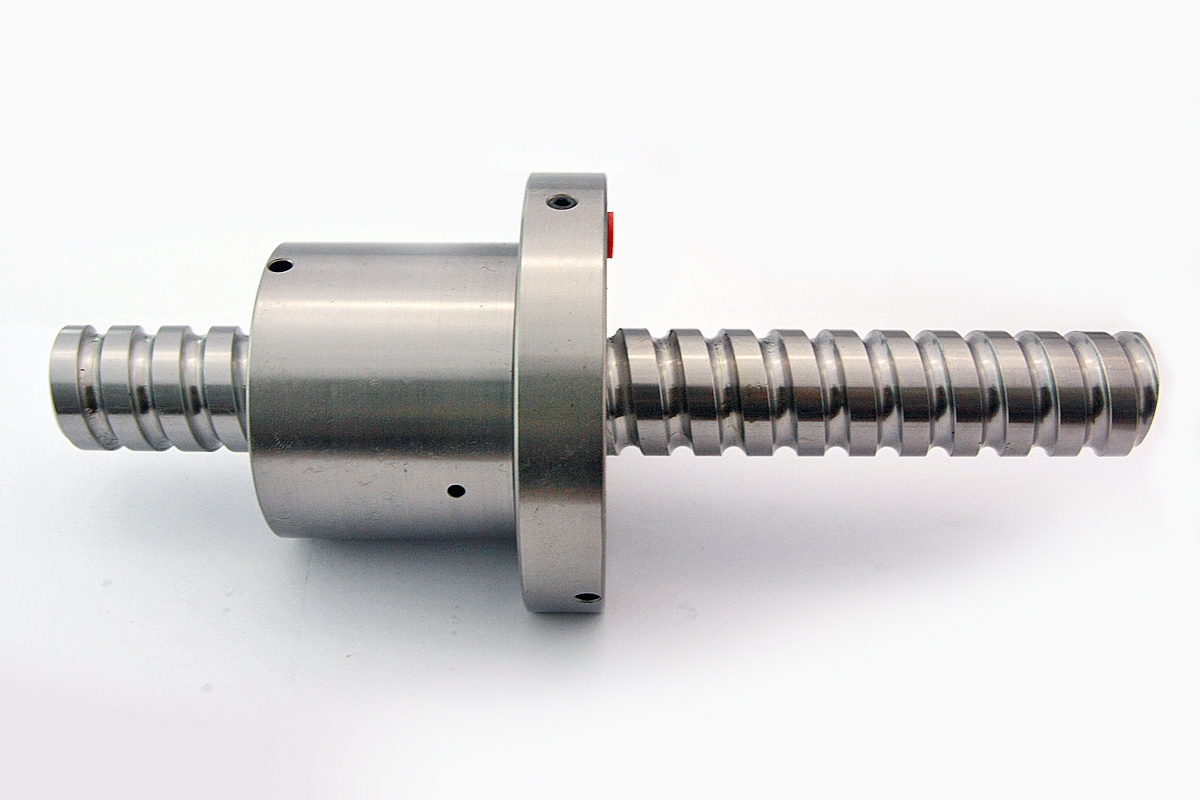

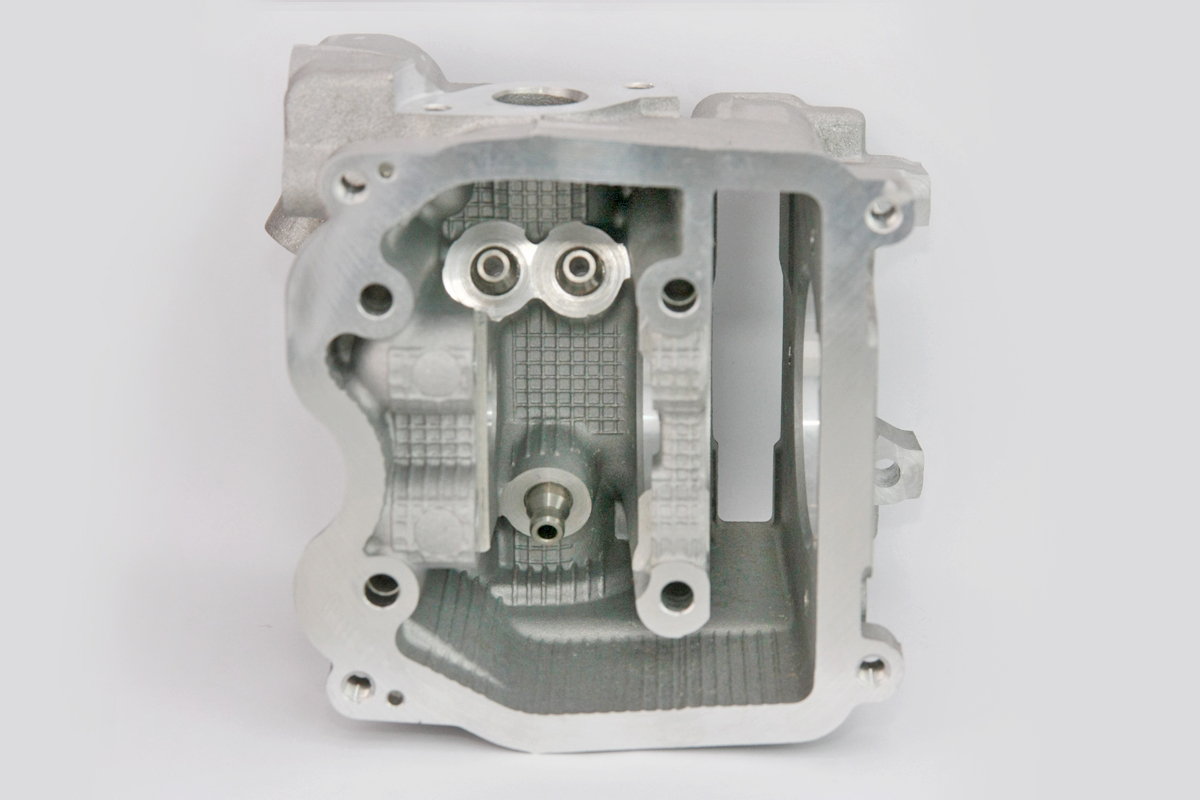

Application :

Lubricant for cutting processes which has been used on steels, SUS and non-ferrous.

Merit :

- Improvement in lifespan of tools.

- Improvement in smoothing the roughness on surface after cutting process.

- Avoid processing departure on the material.

- Upgrade the precision during production.

- Energy saving.

Benefit :

- Tested under various conditions

- Broaching

- Grinding.

- Drilling, Tapping.

- Milling, Turning and Lathes.

Product Line :

- Vegetable Synthesized oil

- - Does not contain the chlorine、sulfur、metal E.P. additives.

- - Environment friendly.

- - Suitable for mist application(Space, energy and resource saving)

- Non-Chlorine Type

- - No problem with the disuse oils.

- - Does not have adverse effects, such as

- - Does not destroy ozone layer and damage the human body.

corrosiveness, to oil seal, resin, and coating.

- Non-Mist Type

- - Minimizes concentration of oil mist in air.

- - Improves working environment.

- - Decreases usage.

- - Lowers the cost of mist-collecting.

| Item |

Appearance |

Density g/cm³ |

Viscosity 40°C;cst |

Flash Point °C |

Etched Copper Plate | Application |

|

| 100°C,1hr | 150°C,1hr | ||||||

| C-102G | Light Yellow | 0.86 | 9.7 | >200 | 1(Non-Active) | 1(Non-Active) | Chlorine free; for aluminum spray type cutting oil |

| C-109W | Transparent | 0.84 | 10 | >160 | 1(Non-Active) | 1(Non-Active) | Chlorine free; for non-ferrous metal low viscosity cutting oil |

| C-111S | Yellow | 0.89 | 23 | >160 | 1(Non-Active) | 1(Non-Active) | Steel drilling and small aperture tapping process |

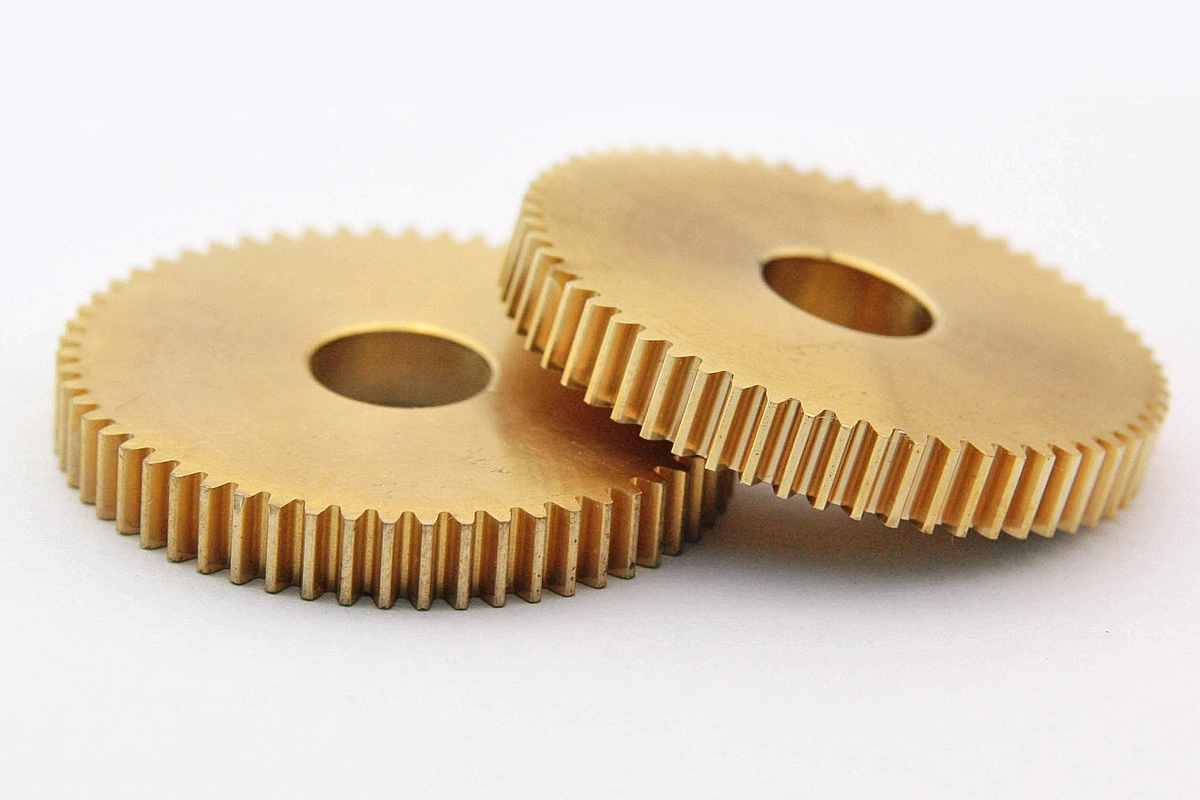

| C-1118F | Yellow | 0.94 | 23 | >170 | 1(Non-Active) | 4(Active) | Sliding head, gear cutting, gear hobbing and gear skiving |

| C-120H | Yellow | 0.91 | 25 | >130 | 4(Active) | — | Steel drilling, reaming, tapping and broaching process |

| C-122DW | Light Brown | 0.89 | 10 | >140 | 4(Active) | — | Low viscosity; for automatic steel cutting machine process |

| C-128B | Yellow | 0.88 | 15 | >160 | 4(Active) | — | Steel; drilling, BTA and gun drilling process |

| C-138TP |

Yellow |

0.93 |

32 |

>160 |

4(Active) |

— |

Stainless steel and steel; the automatic machine (tapping, turning, cutting, drilling)process |

| C-142MK | Dark Brown | 0.91 | 25 | >160 | 2(Non-Active) | 4(Active) | Gear hobbing, gear cutting and MC cutting process |

| C-145E | Red Brown | 0.86 | 8 | >80 | 1(Non-Active) | 4(Active) | Steel boring process |

| C-156 | Yellow | 0.94 | 29 | >150 | 1(Non-Active) | 4(Active) | Processing of steel, stainless steel and non-ferrous metals |

| C-164M |

Light Brown |

0.92 |

14 |

>160 |

4(Active) |

— |

Chlorine free; low viscosity; drilling, tapping and broaching process of steel |

| C-167A |

Brown |

0.84 |

14 |

>170 |

1(Non-Active) |

4(Active) |

Chlorine free; high-end cutting oil of alloy steel, carbon steel gear cutting process |

| C-171H |

Light Brown |

0.88 |

25 |

>160 |

4(Active) |

— |

Chlorine free; steel tapping process; automatic machine process; aluminum alloy process |

| C-184B | Light Brown | 0.79 | 1.5 | >50 | 1(Non-Active) | 1(Non-Active) | Chlorine free; thin plate tapping process and boring process |

| C-1100I |

Transparent |

0.8 |

3.5 |

>70 |

1(Non-Active) |

1(Non-Active) |

The electrical discharge process oil of the plastic die, cast die, forging die, and stamping dies, ect. |

| C-1125V | Yellow | 0.95 | 33 | >160 | 4(Active) | — | C-138TP performance enhancement product |

| C-1127Q |

Brown |

0.89 |

13 |

>160 |

4(Active) |

— |

Stainless steel and steel; low viscosity; the automatic machine(tapping, turning, cutting, drilling)process |

| C-1148R | Brown | 0.90 | 20 | >160 | 1(Non-Active) | 4(Active) | Gear hobbing, gear cutting, MC cutting, and gear skiving process |

| C-1152U |

White |

0.94 |

40 |

>160 |

4(Active) |

— |

Used for turning, cutting, drilling and other processing of stainless steel, steel, titanium alloy |

| C-1153TX | White | 0.99 | 24 | >150 | 4(Active) | — | Steel, stainless steel and alloy tool steel; tapping |

| C-1163B | Light Brown | 0.89 | 24 | >160 | 4(Active) | — | Chlorine free; drilling, fluteless tapping and reaming process |

| C-1163XA | Light Brown | 0.89 | 22 | >160 | 4(Active) | — | C-1163B performance enhancement product |

| C-1163XH | Light Brown | 0.88 | 20 | >160 | 4(Active) | — | C-1163XA performance enhancement product |

| C-1177C | Green | 0.87 | 32 | >180 | 1(Non-Active) | 4(Active) | Non-chlorine series, for gear cutting, gear hobbing, and gear scraping |

| C-1181P | Transparent | 0.80 | 5.5 | >140 | 1(Non-Active) | 1(Non-Active) | Synthetic oil, suitable for grinding of tungsten steel |