Pressing Oil SUNPRESS

Introduction Products : Lubricants for stamping and forming applications of metal

Application : Used in stamping and forming processes to reduce friction between the dies and work piece.

Merit :

- Anti-wear properties for tools . Extended tool life.

- Anti-seizure properties.

- Decrease the processes.。

- Reduce friction

Benefit :

The role of the lubricant in pressworking operations is to reduce the friction between dies and work piece thereby minimizing tool wear and galling. During pressworking operations, the friction between dies and work piece is in the mixture condition of fluid lubrication and film boundary lubrication. In the fluid film lubricating area, friction resistance is low and in the boundary lubrication area it becomes high.

SUNPRESS maintains good fluid film lubrication when friction is low, and when it reaches the boundary lubrication area, it demonstrates superior extreme pressure performance.

Tests under various situations : In order to meet diversified requests for product testing, we have been conducting not only various laboratory tests but also tests using actual production scale pressworking equipment.

| Item | Viscosity(40°C;cst) | Flash Point(°C) | Main Composition | Merit and Application |

| S-101J | 1.3 | >50 | Oiliness Additive | Steel plate, non-ferrous metal stamping, lamination process; less residual of oil |

| S-103J | 1.4 | >50 | Oiliness Additive | Steel plate, non-ferrous metal stamping, lamination process; no residual |

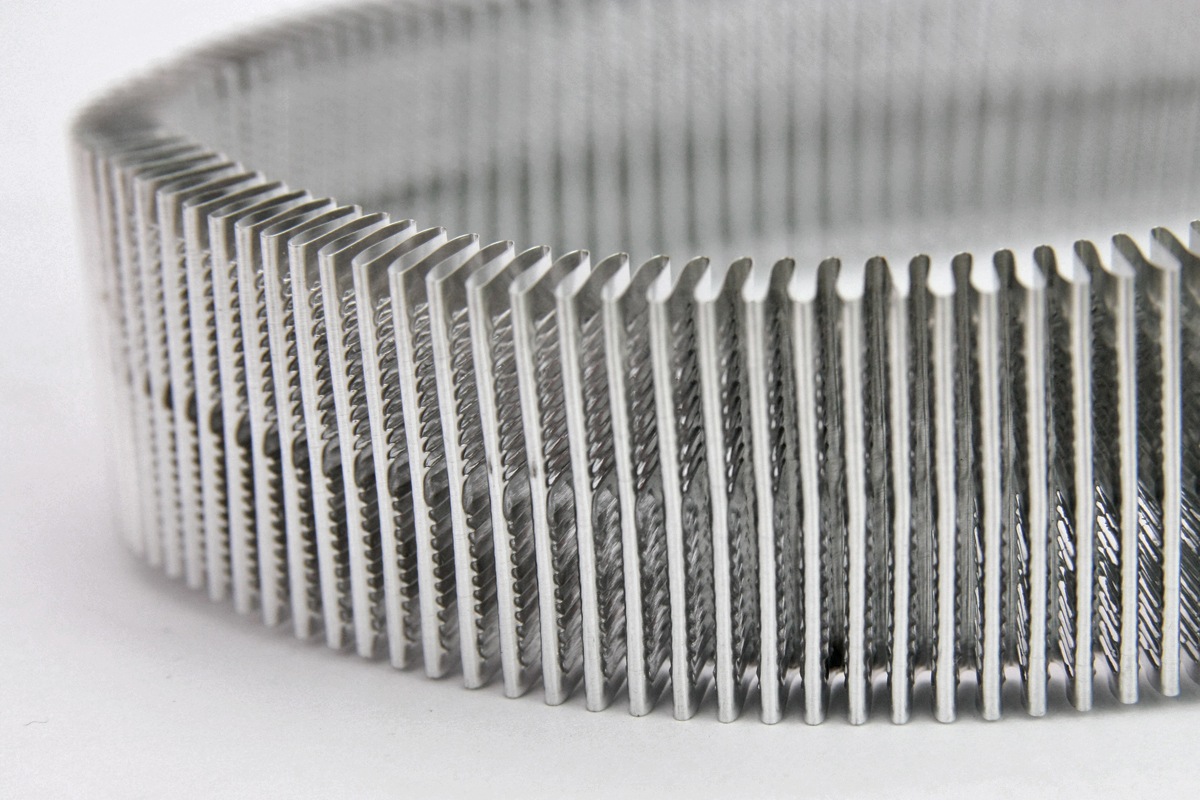

| S-105J | 3 | >80 | Oiliness Additive | Dry type oil product for making air condition aluminum heat sink |

| S-106J | 1.6 | >62 | Oiliness Additive | Steel, galvanized and aluminum thin plate process; easy cleaning |

| S-114A |

2.3 |

>62 |

Oiliness Additive CL Type |

Steel, stainless steel and non-ferrous metal stamping and lamination process |

| S-162A |

1.5 |

>62 |

Oiliness Additive CL Type |

Applied to Silicon steel; the workpiece can be annealed without cleaning; for compressor industry |

| S-1102F | 1.8 | >70 | Oiliness Additive | Steal, non-ferrous metal thin plate stamping process; easy cleaning |

| Item | Viscosity(40°C;cst) | Flash Point(°C) | Main Composition | Merit and Application |

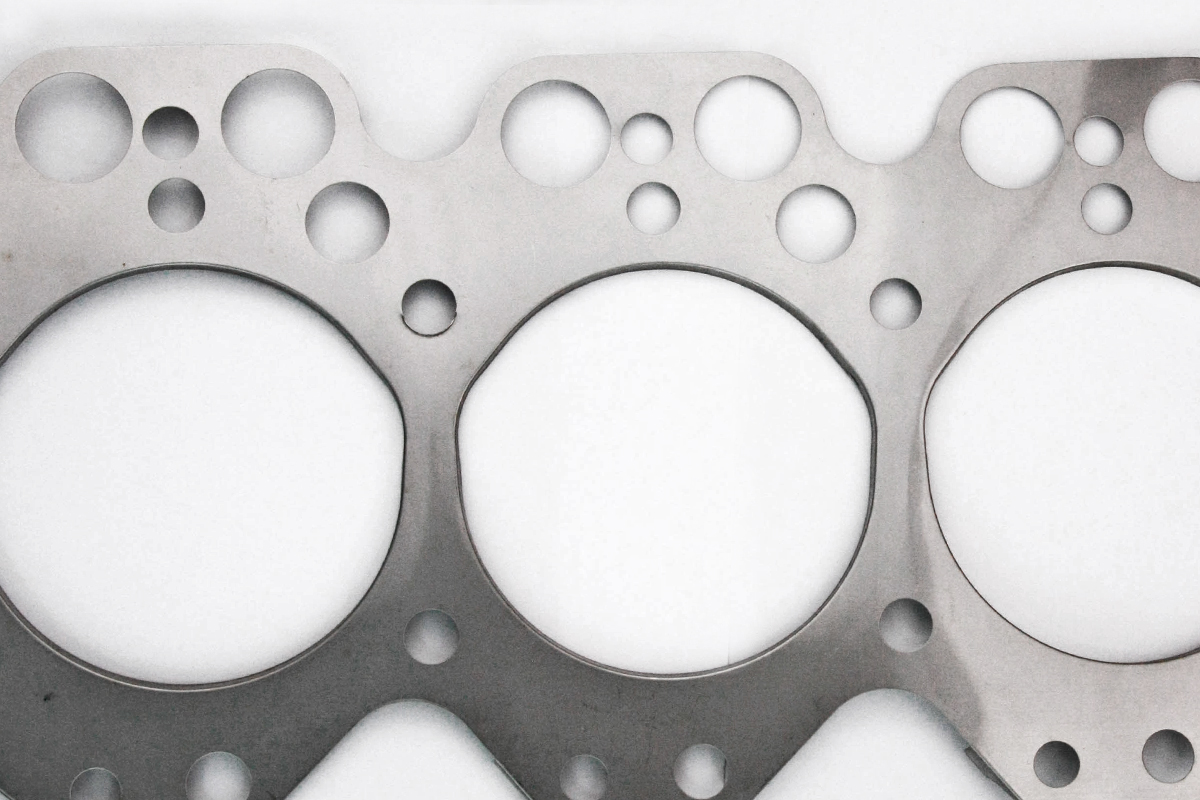

| FB-120 | 90 | >170 | Oiliness Additive, S, CL Type | Used for fine blanking press process |

| FB-526 | 90 | >200 | Oiliness Additive, CL Type | Used for fine blanking press process |

| FB-585 | 79 | >180 | Oiliness Additive, S, FM Type | Chlorine free; low viscosity FB oil |

| FB-688P | 103 | >160 | Oiliness Additive, P, S, FM Type | Chlorine free; FB oil |

| FB-788F | 156 | >160 | Oiliness Additive, P, S, FM Type | Chlorine free; high performance FB oil for thick plate and hard process |

| FB-888F | 202 | >180 | Oiliness Additive ,P, S, FM Type | Chlorine free; high performance FB oil, high oil film strength |

| Item | Viscosity(40°C;cst) | Flash Point(°C) | Main Composition | Merit and Application |

| S-284 | 16 | >150 | Oiliness Additive, S, FM Type | Low viscosity stamping oil for precision stamping process |

| S-326 |

35 |

>180 |

Oiliness Additive, CL Type |

Low-viscosity high-performance press plate processing oil, for forming processing of ordinary steel plates and stainless steel plates |

| S-374A | 40 | >200 | Oiliness Additive, P, S Type | Chlorine free; steel and stainless steel plate stamping and forming process |

| S-478 |

54 |

>170 |

Oiliness Additive, P, S Type |

Good wear resistance and forming properties; prevent workpiece from flawing and cracking |

| S-534 |

96 |

>200 |

Oiliness Additive, S Type |

Good anti-rust property and easily being cleaned; applied to continuous type automatic producing machines |

| S-602 | 100 | >200 | Oiliness Additive | Steel plate, non-ferrous metal and aluminum stamping and forming process |

| S-605 | 138 | >150 | Oiliness Additive | Aluminum hard process and 9-Volt battery metal case forming |

| S-774 | 185 | >160 | Oiliness Additive, P, S Type | Thick plate and stainless steel plate hard process; Chlorine free |

| S-2225TR | 20 | >150 | Oiliness Additive, CL Type | Steel plate, stainless steel plate; aluminum, copper and copper alloy |

| S-2860B | 200 | >130 | Oiliness Additive, P Type | Difficult to process aluminum |

| S-541S | 162 | >200 | Oiliness Additive, S, CL Type | Steel plate forming process |

| S-5516S | 110 | >200 | Oiliness Additive, S, CL Type | Battery case forming process |

| S-5690 | 145 | >200 | Oiliness Additive, S Type | Battery case forming process ; Chlorine free |

| S-830BY | 700-800 | >200 | Oiliness Additive, CL Type | Stainless plate deep drawing process; applied to drawing pots and cups |

| S-9920R | 725 | >200 | S Type, CL Type | Iron, steel deep drawing process |

| Type | Item | Appearance | PH | Percentage | Additive | Merit and Application |

| Emulsification | SE-8A | White Paste | 8.6(20 %) | 100 % ~ 10 % |

Oiliness Additive Solid Lubricant |

Thick plate stamping process; good wear resistance |

| SE-8P | White Paste | 8.4(33.3 %) | Thick plate, steel plate and stainless steel plate stamping process | |||

| SE-138C | Brown Liquid | 9.7(2.5 %) | Sulfur Additive Chlorine Additive |

Carbon steel plate, surface treatment steel plate; oil film can be removed by alkaline cleaner after process |

||

| Semi-Synthetic | SE-65CP | Brown Liquid | 8.5(20 %) | Oiliness Additive Phosphorus Additive |

Carbon steel plate and stainless steel plate; good burn resistance, anti-rust and forming properties |

|

| SE-65CR | Brown Liquid | 9.1(20 %) | Steel plate and stainless steel plate; good burn resistance, anti-rust and anti-spoilage properties |